Welding

Program Description

AAS in Welding Technology STEM Emphasis degree is no longer available to new students. Students considering a transfer pathway can choose the traditional AAS degree and complete an AGEC-A certificate to prepare to enter a university.

The Welding program and certificates offers a selection of technology courses and programs that prepares graduates a career in welding. The content and instruction within welding centers on the traditional welding processes and practices of oxyacetylene welding and cutting, shielded metal arc (stick), gas tungsten arc (Tig-Heliarc), gas metal arc (MIG), as well as the non-traditional processes of plasma arc, resistance welding, fluxed core arc, submerged arc, and electron beam. Completion of the different sequences of instruction within the welding department prepares graduates for a rewarding career in metal fabrication, maintenance, education, supervision, sales and service, as well as many other opportunities associated with welding technology.

Graduates of the welding program or certificates will learn a wide range of skills and gain industry specific experience in:

- Entry-level weldments.

- Analyzing welding applications and quantifying the needed materials and equipment to perform tasks.

- FCAW (Flux Core Arc Welding) and its applications.

- Oxyacetylene welding

- Joining plates by the SMAW process.

- Gas tungsten arc (TIG-Heliarc) welding.

- Gas metal arc (MIG-Wirefeeders) welding (GMAW).

- Procedures in welding design and metal fabrication.

- The science, technology and art of welding specific to processes using semiautomatic, automation and simulation control technology.

Have questions about this program?

Schedule NowDegree(s) / Certificates(s)

Career Outlook

Successful completion of this program can open doors to various employment opportunities, many of which require further higher education at the university level. Below are examples of related occupations and their annual mean wages in Arizona, based on career and wage data from Pipeline AZ, which utilizes government sources for its reports and forecasts.

Description

Set up, operate, or tend heating equipment, such as heat-treating furnaces, flame-hardening machines, induction machines, soaking pits, or vacuum equipment to temper, harden, anneal, or heat treat metal or plastic objects.

Duties/Tasks

- Read production schedules and work orders to determine processing sequences, furnace temperatures, and heat cycle requirements for objects to be heat-treated.

- Record times that parts are removed from furnaces to document that objects have attained specified temperatures for specified times.

- Adjust controls to maintain temperatures and heating times, using thermal instruments and charts, dials and gauges of furnaces, and color of stock in furnaces to make setting determinations.

- Start conveyors and open furnace doors to load stock, or signal crane operators to uncover soaking pits and lower ingots into them.

- Set up and operate or tend machines, such as furnaces, baths, flame-hardening machines, and electronic induction machines, that harden, anneal, and heat-treat metal.

- Determine flame temperatures, current frequencies, heating cycles, and induction heating coils needed, based on degree of hardness required and properties of stock to be treated.

- Determine types and temperatures of baths and quenching media needed to attain specified part hardness, toughness, and ductility, using heat-treating charts and knowledge of methods, equipment, and metals.

- Set up and operate die-quenching machines to prevent parts from warping.

- Examine parts to ensure metal shades and colors conform to specifications, using knowledge of metal heat-treating.

- Set and adjust speeds of reels and conveyors for prescribed time cycles to pass parts through continuous furnaces.

Salary Information (AZ)

$45,220

$33,830

$44,140

$60,350

$21.74

$16.26

$21.00

$29.02

Typical Education Level

High School Diploma

Description

Lay out reference points and dimensions on metal or plastic stock or workpieces, such as sheets, plates, tubes, structural shapes, castings, or machine parts, for further processing. Includes shipfitters.

Duties/Tasks

- Mark curves, lines, holes, dimensions, and welding symbols onto workpieces, using scribes, soapstones, punches, and hand drills.

- Plan locations and sequences of cutting, drilling, bending, rolling, punching, and welding operations, using compasses, protractors, dividers, and rules.

- Fit and align fabricated parts to be welded or assembled.

- Locate center lines and verify template positions, using measuring instruments such as gauge blocks, height gauges, and dial indicators.

- Plan and develop layouts from blueprints and templates, applying knowledge of trigonometry, design, effects of heat, and properties of metals.

- Lay out and fabricate metal structural parts such as plates, bulkheads, and frames.

- Compute layout dimensions, and determine and mark reference points on metal stock or workpieces for further processing, such as welding and assembly.

- Lift and position workpieces in relation to surface plates, manually or with hoists, and using parallel blocks and angle plates.

- Install doors, hatches, brackets, and clips.

- Brace parts in position within hulls or ships for riveting or welding.

Typical Education Level

High School Diploma

Description

Fabricate, assemble, install, and repair sheet metal products and equipment, such as ducts, control boxes, drainpipes, and furnace casings. Work may involve any of the following: setting up and operating fabricating machines to cut, bend, and straighten sheet metal; shaping metal over anvils, blocks, or forms using hammer; operating soldering and welding equipment to join sheet metal parts; or inspecting, assembling, and smoothing seams and joints of burred surfaces. Includes sheet metal duct installers who install prefabricated sheet metal ducts used for heating, air conditioning, or other purposes.

Duties/Tasks

- Convert blueprints into shop drawings to be followed in the construction or assembly of sheet metal products.

- Determine project requirements, such as scope, assembly sequences, or required methods or materials, using blueprints, drawings, or written or verbal instructions.

- Lay out, measure, and mark dimensions and reference lines on material, such as roofing panels, using calculators, scribes, dividers, squares, or rulers.

- Fasten seams or joints together with welds, bolts, cement, rivets, solder, caulks, metal drive clips, or bonds to assemble components into products or to repair sheet metal items.

- Trim, file, grind, deburr, buff, or smooth surfaces, seams, or joints of assembled parts, using hand tools or portable power tools.

- Fabricate ducts for high efficiency heating, ventilating, and air conditioning (HVAC) systems to maximize efficiency of systems.

- Select gauges or types of sheet metal or nonmetallic material, according to product specifications.

- Finish parts, using hacksaws or hand, rotary, or squaring shears.

- Develop or lay out patterns, using computerized metalworking equipment.

- Maneuver completed roofing units into position for installation.

Salary Information (AZ)

$49,130

$32,410

$47,890

$63,030

$23.62

$15.58

$23.00

$30.30

Typical Education Level

High School Diploma

Description

Raise, place, and unite iron or steel girders, columns, and other structural members to form completed structures or structural frameworks. May erect metal storage tanks and assemble prefabricated metal buildings.

Duties/Tasks

- Read specifications or blueprints to determine the locations, quantities, or sizes of materials required.

- Connect columns, beams, and girders with bolts, following blueprints and instructions from supervisors.

- Bolt aligned structural steel members in position for permanent riveting, bolting, or welding into place.

- Fasten structural steel members to hoist cables, using chains, cables, or rope.

- Hoist steel beams, girders, or columns into place, using cranes or signaling hoisting equipment operators to lift and position structural steel members.

- Verify vertical and horizontal alignment of structural steel members, using plumb bobs, laser equipment, transits, or levels.

- Cut, bend, or weld steel pieces, using metal shears, torches, or welding equipment.

- Erect metal or precast concrete components for structures, such as buildings, bridges, dams, towers, storage tanks, fences, or highway guard rails.

- Force structural steel members into final positions, using turnbuckles, crowbars, jacks, or hand tools.

- Pull, push, or pry structural steel members into approximate positions for bolting into place.

Salary Information (AZ)

$51,320

$37,020

$48,060

$75,920

$24.67

$17.80

$23.00

$36.50

Typical Education Level

High School Diploma

Description

Use hand-welding, flame-cutting, hand-soldering, or brazing equipment to weld or join metal components or to fill holes, indentations, or seams of fabricated metal products.

Duties/Tasks

- Operate safety equipment and use safe work habits.

- Examine workpieces for defects and measure workpieces with straightedges or templates to ensure conformance with specifications.

- Weld components in flat, vertical, or overhead positions.

- Detect faulty operation of equipment or defective materials and notify supervisors.

- Recognize, set up, and operate hand and power tools common to the welding trade, such as shielded metal arc and gas metal arc welding equipment.

- Select and install torches, torch tips, filler rods, and flux, according to welding chart specifications or types and thicknesses of metals.

- Mark or tag material with proper job number, piece marks, and other identifying marks as required.

- Determine required equipment and welding methods, applying knowledge of metallurgy, geometry, and welding techniques.

- Prepare all material surfaces to be welded, ensuring that there is no loose or thick scale, slag, rust, moisture, grease, or other foreign matter.

- Check grooves, angles, or gap allowances, using micrometers, calipers, and precision measuring instruments.

Salary Information (AZ)

$48,520

$33,680

$46,970

$66,370

$23.33

$16.19

$22.00

$31.91

Typical Education Level

High School Diploma

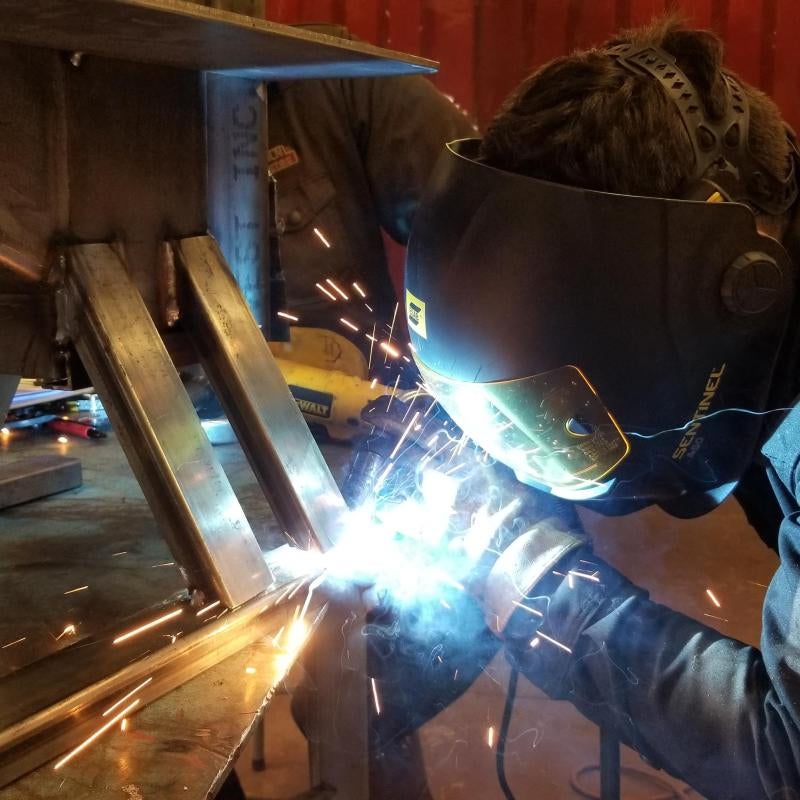

Classroom/Lab Tour

Program Photos

Contact Information

Department Contact(s)

Career and Technical Education

Hours of Operation

- Normal Hours

- Monday - Thursday: 7:00am-5:00pm

Faculty/Staff Contact(s)

| Name | Title | Phone | |

|---|---|---|---|

| Noberto Alvarado | Professor of Welding | (928) 344-7570 | Noberto.Alvarado@azwestern.edu |

| Teresa Livingston | Administrative Assistant to the Executive Director & Dean CTE Programs | (928) 344-7752 | Teresa.Livingston@azwestern.edu |